Quality & Testing

Advanced testing capabilities and quality management systems ensuring excellence in every product we manufacture

Testing Equipment

State-of-the-art quality control and inspection equipment

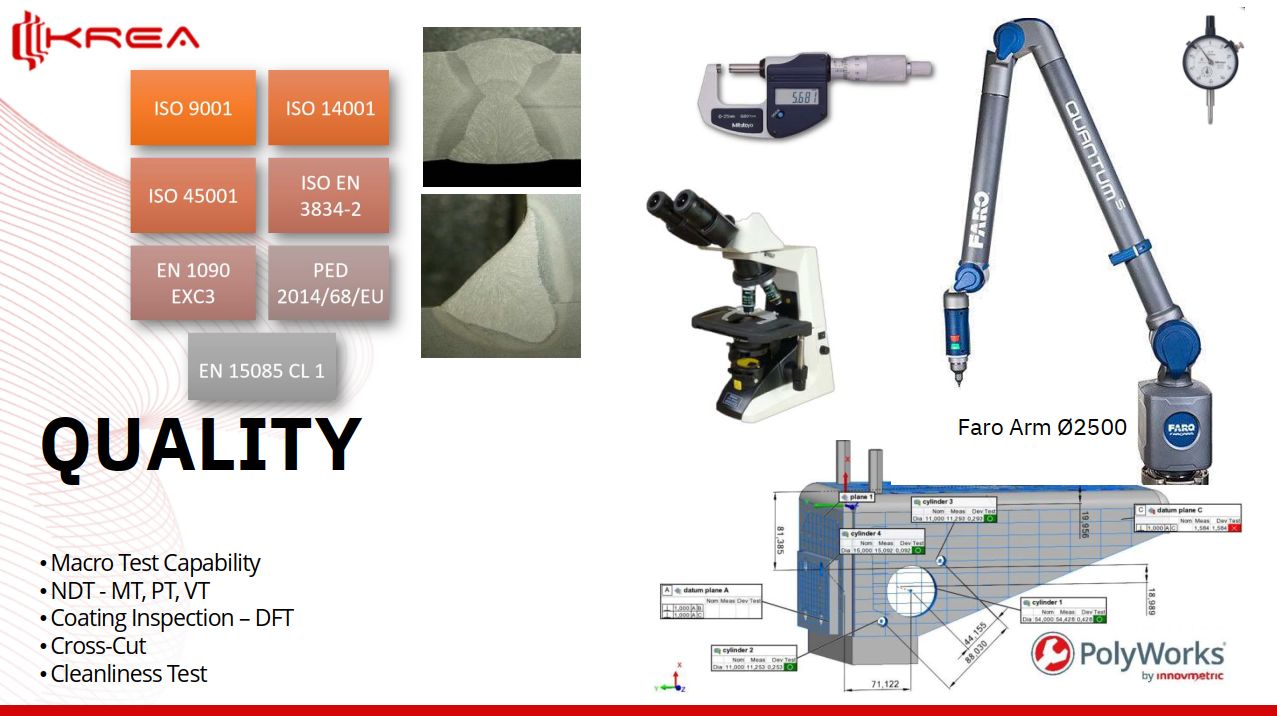

FARO Arm Ø2500

High-precision 3D measurement system for dimensional inspection and quality control

Macro Test Capability

Metallographic analysis for weld quality and material structure verification

NDT Testing Suite

Non-Destructive Testing methods for comprehensive quality inspection

Coating Quality Tests

Advanced coating inspection and verification procedures

Our Quality Infrastructure

Advanced testing capabilities with industry-leading equipment and certifications

Quality Management

Systematic approach to quality assurance and continuous improvement

FMEA Analysis

Failure Mode and Effects Analysis for risk prevention

Control Plans

Structured quality control throughout production

KPI Monitoring

Key Performance Indicators for quality excellence

Cpk Analysis

Process capability monitoring and improvement

Advanced Quality Systems

Industry-leading quality planning and management methodologies

QMS - Quality Management System

ISO 9001:2015 certified quality management system ensuring consistent quality across all processes.

- Document control & procedures

- Internal audit program

- Corrective & preventive actions

- Management review process

- Continuous improvement culture

- Customer satisfaction monitoring

APQP - Advanced Product Quality Planning

Structured framework for developing products that satisfy customers through comprehensive planning.

Customer requirements & feasibility

DFMEA & design verification

PFMEA & control plans

Production trial & measurement systems

Full production & continuous improvement

PPAP - Production Part Approval Process

Comprehensive documentation package demonstrating production capability and customer approval.

- Design records & specifications

- Engineering change documents

- Process flow diagrams

- PFMEA documentation

- Control plan

- Measurement system analysis (MSA)

- Dimensional results & material test reports

- Initial process capability (Cpk)

- Qualified laboratory documentation

- Appearance approval report (AAR)

- Sample production parts

- Master sample

- Checking aids

- Customer-specific requirements

- Part submission warrant (PSW)

Quality Metrics

Real-time performance indicators demonstrating our commitment to excellence

Quality Certifications

Internationally recognized standards backing our quality commitment

ISO 9001:2015

Quality Management System

ISO 3834-2:2021

Welding Quality Requirements

EN 1090-1

Structural Steelwork

EN 15085

Railway Applications

Quality You Can Trust

Experience the KREA difference - where quality is not just measured, but guaranteed